|

Wuxi Friendship Machinery Co., Ltd

|

Gold Index: 8002

You are here: home > 5 Ribs Covered 1000mm PU Sandwich Panel Production Line With Double-Belt Conveyor

5 Ribs Covered 1000mm PU Sandwich Panel Production Line With Double-Belt Conveyor

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

AIA-1

Rock Wool/Glass Wool/PU Sandw

Rock Wool/Glass Wool/PU Sandwich Panel Production Line

With Double-Belt Conveyor

Introduction of machine

- A combination production line,wich can produce PU,rock wool,glass wool sandwich panels,with the function of edge foaming and sealing for rockwool,glass wool panels.

- High pressure glue spraying unit:glue is sprayed on up and down steels sheet directly,wich saves glue and insures quality by maximing the stickness of glue.

- Rotary type:block type,two turning.It is the most advanced and reliable technology,suitable for producing low density glass wool panels.

- Picture of production line

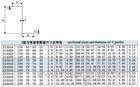

| NO. | Composing of product line | Amount | |

| 1 | Panel Roll Forming Machine | main roll forming machine | 1 |

| De-coiler for 1040mm in width | 1 | ||

| 2 | Panel Roll Forming Machine | main roll forming machine(double layer) | 1 |

| De-coiler for 1200mm in width | 1 | ||

| 3 | PU Sandwich Production Line | PU two component Liquid mixing and injecting section for foaming | 1 |

| Panel automatically cutting system | 1 | ||

| PU solidify conveyor system | 1 |

Primary technology parameters of PU sandwich panel product line

- Production Material(mm):(0.25-1.0)×L, yield strength≤G300 Colored steel

- Production speed:4-8 M/min

- Production type: totally continuous production with PLC controlling

- PU foam thickness: 25-100mm

- Composite structure:position fixed by double rubber tracker

- Foaming system: totally automatically continuous foaming, quantity of foaming could be stepless adjustable

- Power of production ≥ 22KW

- Total power ≥ 35 KW

- Cutting:pneumatic piston driving, non-stop cutting via sliding table

- Electronic controlling system: full-frequency PLC controlling system

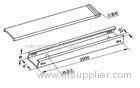

Uncoiler roll forming machine

- Excellent groove design and forming technics of roll forming machine combine with aided design of German copre software which can release whole stress and reduce waves while roll forming and keep the final products with planeness.

- Two-side projecting shaft roll former,rollers can be fixed on two sides shafts.

- Fast vertical loading of roll forming stations

- Roll forming machine on two side can be bidirectional changed,matched with double-belt conveyor to keep center.

- Width adjusting device by using high-precision ball screw and linear guide,accuracy tolerance+/-0.5mm.

- Pre-heating room is made of 50mm PU Sandwich panel as fence,which decreases heat-loss substantially.

PU Sandwich foaming line

- Two sets of conveyor rack: up conveyor is about 24m, down conveyor is about 30m.They lead the steel sheet from the roll forming machine to preheating room and to foaming,to cutting.

- One preheating room: It is built by heat-insulation material, and it could heat up the steel sheet to 25-38 by heater.

- One set of PU two component Liquid mixing and injecting section for foaming : it adopt Chinese high pressure pump. It have the temperature control system and material-level monitoring system. The tank of the material is about 150L. Two tanks.

- Foaming and double rubber device include motor driver system to make panel.

- The width of belt board is 1250mm, the range of adjusting distance between upper and lower frame belt board: min 25mm, max 200mm. And the range of adjusting thickness of sandwich panel :30mm,50mm,100mm.(30-50 for celling , 50-100 for wall)

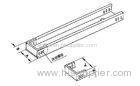

Double-belt conveyor

- The double belt adopts two-stage drive (belt plate iis driven by auxiliary fine-pitch chain),which eliminates the mechanical nonsynchronous.

- The double belt also is equipped flexible tight system to make the operation more stable and reliable.

Related Search

PU Sandwich Panel

Pu Conveyor Belt

Sandwich Panel Line

Double Pipe Production Line

Panel Production Line

Aluminum Composite Panel Production Line

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Wuxi Friendship Machinery Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)

You May Like:

Printable Page

Bookmark this page

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español

Copyright © HiSupplier.com Online Inc. All Rights Reserved.