|

Wuxi Friendship Machinery Co., Ltd

|

Gold Index: 8002

You are here: home > Bunkers Corrugated Sheet Roll Forming Machine For Drainage Channels

Bunkers Corrugated Sheet Roll Forming Machine For Drainage Channels

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

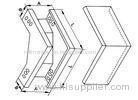

Bunkers Corrugated Sheet Roll Forming Machine For Drainage Channels

<

Bunkers Corrugated Sheet Roll Forming Machine For Drainage Channels

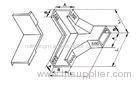

Corrugated steel culvert applications

- Corrugated steel culvert is an alternative pipe culvert, cover culvert, box culvert, arch culvert and bridges of high-quality road building materials, can be used for road and rail transverse channels, tunnels, culverts, drainage channels and bunkers and other projects.

- Road and rail: culverts, channels, bridges, tunnels, tunnel culvert repair, temporary pavement, infiltration wells

- Municipal and construction: a common ditch, light cable protection, drainage ditches, crane cofferdam, vertical pile shell

- Coal mine: mineral pipeline, personnel and mining machinery channels, shaft

- Civil: power plant flue gas, grain storage warehouse, fermentation tanks, wind power

- Military: Military service road, air channels, evacuation routes

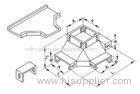

Advantages of corrugated steel culvert

- Corrugated steel culvert both rigid and flexible; structure of reasonable force, load distribution, a certain resistance to deformation.

- Use of standardized designs, factory-scale production; short production cycle, high efficiency, helps reduce costs and improve quality.

- On-site installation of speed, short construction period, social economic benefit.

- Year-round construction, construction not subject to seasonal effects, not environmental impact.

- Can effectively solve the freezing cold north area of concrete bridges and culverts due to repeated failure problems.

- Especially for long: East soil, expansive soil, soft soil, loess and other special areas, to avoid uneven settlement of foundation deformation caused by the destruction of the culvert.

- Reduce the cement, sand, gravel and other conventional building materials used, environmentally significant.

- Compared with concrete bridges and culverts, the same span corrugated steel culverts and lower total cost.

- Small post maintenance work, maintenance and low cost.

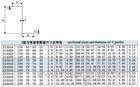

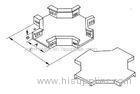

UNITS

| Thickness of the feed | 2.5~5mm | 4~8mm |

| Feed Width | 1250~1500mm | |

| Forming speed | 1~6m/min | |

| The direction of production line | Feed the left (user choice) | |

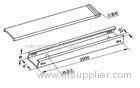

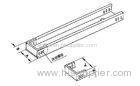

Pictures of machine

Related Search

Roll Forming Machine

Cold Roll Forming Machine

Roof Roll Forming Machine

Sheet Forming Machine

Roll Forming

Corrugated Roll

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi Friendship Machinery Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)