|

Wuxi Friendship Machinery Co., Ltd

|

Gold Index: 8002

You are here: home > Automatic Rack Roll Forming Machine With 5 Ton Uncoiler And 11kw DC Motor

Automatic Rack Roll Forming Machine With 5 Ton Uncoiler And 11kw DC Motor

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Automatic Rack Roll Forming Machine With 5 Ton Uncoile

Automatic Rack Roll Forming Machine With 5 Ton Uncoiler And 11kw DC Motor

Main features of machine

- Width of Coil: Base on customer profile

- Working speed:12-15m/min(Not include cutting)

- Thickness of coil:1.5-2.0mm

- The structure is simple and the appearance of the machine is beautiful because

- we adopt the shape-steel structure and process as a whole after welding. it has the ability of strong loading and stable operation when running the machine.

- All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

- We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

- It is very easy to install the equipment and suitable for producing in the factory.

- The machine has features of low noise and high efficiency.

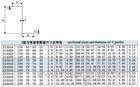

Details of each composition

Roll Station

- Forming Station:17stations

- ASTM52100, polished and coated with chrome HRC58-62°

- Leveling station: 7 rollers ( up three rollers, down four rollers)

- Diameter of roller :76mm

- Material of roller: ASTM1045, polished and coated with chrome HRC58-62°

- Material of main shaft :ASTM1045

- Main power: 11kw DC motor

- Forming thickness :1.5-2.0mm

- Transmission : by single line chain 1.5inch

- Machine adopts new stations to make machine stronger

Cutting

- Machine adopt hydraulic after cutting

- Cutting after forming: Cut the sheet after roll forming to required length

- Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

- Material of blade: D2with heat treatment total 3 cutters

- Length measuring: Automatic length measuring

- Tolerance of length :3m +/- 1.5mm

Uncoiler

- Dimensions :1700mm*1000mm*800mm

- Width of feeding: 300mm

- Capability :5 Ton

- Bound of expand &fight :460mm—510mm

- Mode of expand &fight inner expand &fight by manual

- Way of feeding manual

Control panel Panasonic

- Voltage, Frequency, Phase 380 V, 50 Hz, 3Phase

- Automatic length and quantity measurement

- Computer used to control length & quantity

- Machine will automatically cut to length and stop when required quantity is achieved

- Length inaccuracy can be amended easily

- Control panel Button-type switch and touch screen

- Unit of length millimeter (switched on the control panel)

Hydraulic station

- Hydraulic station power :5.5kw

- Hydraulic pressure: 20Mpa

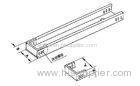

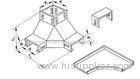

Manual out table

- Jointed by 60mm*40mm tube

- Size:1.0m long*0.8mwide*0.6-1mhigh

- One out table with two support roller

Technological process

Uncoiling—Feeding—Leveling-----Roll forming— Revising—-Cutting—Products

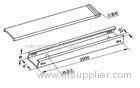

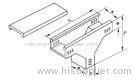

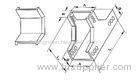

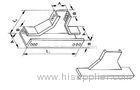

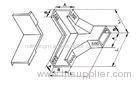

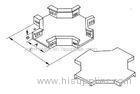

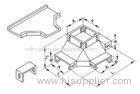

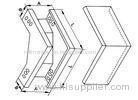

Profile (basis on customer’s require to design)

Related Search

Roll Forming Machine

Cold Roll Forming Machine

Roof Roll Forming Machine

Automatic Forming Machine

Automatic Vacuum Forming Machine

Roll Forming

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Wuxi Friendship Machinery Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)