|

Wuxi Friendship Machinery Co., Ltd

|

Gold Index: 8002

PLC Control Steel Silo Forming Machine

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

PLC Control 2.5mm - 4mm Silo Making Machine 10T For Grain Silo

<sp

PLC Control 2.5mm - 4mm Silo Making Machine 10T For Grain Silo

Main Technical

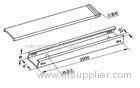

This line includes hydraulic decoiler with coil car, guide, forming, punching, curving, cutting, simple stacker

Material feeding width: max 1250mm, Q235, max thickness: 2mm.

1.Hydraulic Decoiler with coil car:

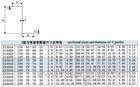

| Max feeding width: | 300-1250mm |

| Max loading capacity: | 10T |

| Inner coil diameter: | 460-560mm |

| Max coil diameter: |

1500mm |

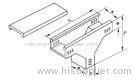

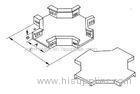

2.Main Forming machine:

3.Incl. steel plate feeding and guide, manual adjusting centering, roll forming.

Preciseness of single wave height and distance: ± 2mm

Plate after forming, plate surface and edge smooth, no obvious scratch.

Forming station: 20 stations in total (16 stations, 2 stations for reshaping, first station roller has feeding

function, two ends rollers has guiding function) , roller material GCr15.

Motor:2 sets, 15kw each.

Speed: 6-15mm/min including punching, not including cutting.

Machine structure: Stand column and gearbox driving for each stations.

Control: by PLC Taiwan Delta, touch screen Chinese brand, with remote control.

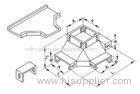

4.Punching part:

Non-stop tracking punching

Servo motor 5.5kw, encoder, ball screw transmission

Hydraulic station by China

Punching preciseness:

Hole: +0.3mm

hole distance (width direction): ±1mm

hole distance (length direction): ±2mm

Screw hole: smooth, shape good

Punching die: Cr12MoV material, heat treatment, 60-62HRC. One set of punching head with one line.

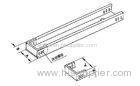

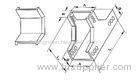

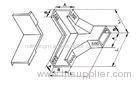

5.Curving machine

Curving way: three roller curving

Feeding width: 1500mm

Speed: the same speed as main forming machine.

Max curving diameter: 2m.

Structure: stand column.

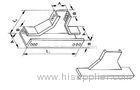

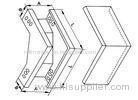

6.Cutting part:

Share hydraulic station with punching part.

Cutting way: hydraulic cutting, cutting angle adjustable, can match with curving.

Length accuracy: ±2mm

Cutting blade: Cr12MoV, heat treatment, 60-62HRC

7.Stacker

After cutting, finished product output by stacker.

Automatic conveying, stacking by hand.

Introduction of company

We, Friendship Machinery Co.,Ltd, attaches great importance on technology innovation,progress has been made on scientific management as well as Co.,culture.China leading expert in designing and manufacturing equipments for welding and cutting, automation system and metal works. We use and produce high-technology utilizing the most available robotic and automatic techniques. Every work is uncompromisingly designed to improve our clients' competitiveness and productivity.

We invest more on developing roll forming machine such as Metal roof & wall panels machines,C&Z purlin machines drywall Stud-track forming machines,Metal decks machines,No-girder and Column curves forming machine,Guard rails forming machines,Downspout pipes forming machines and so on.With fast development ,very short period for construction and beautiful external appearance,as well reasonable price was occupied in the market of building industry.

EXCELLENT QUALITY AND COMPETITIVE PRICE!

CHOOSE US , CHOOSE THE BEST!

Thank you for your time!

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi Friendship Machinery Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)